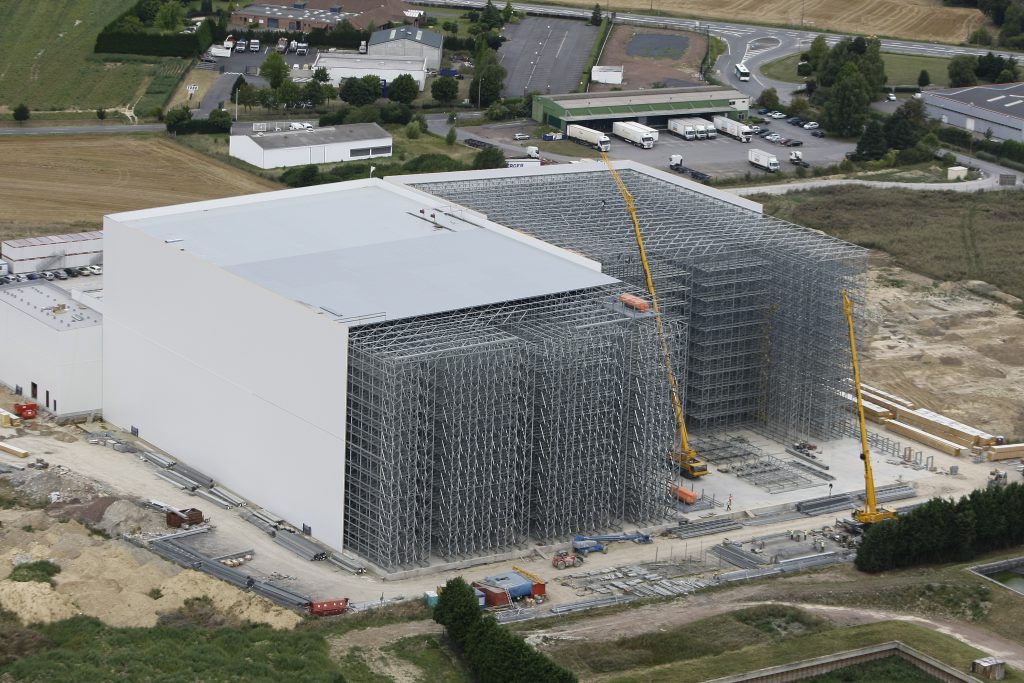

Roma was commissioned by Kloosterboer to install the insulated facade and roof cladding of this high-bay deep-freeze warehouse in Harnes (France) for the fully automated storage of McCain potato products.

The building measures a staggering 97 x 110 x 38 metres and counts 68.000 pallet locations.

For fire safety reasons, the deep-freeze warehouse is divided into two storage zones which are separated by a 1.5-metre-wide corridor. An oxygen reduction system has also been installed. The temperature inside the deep-freeze warehouse is -22 degrees Celsius.

Kloosterboer chose the silo construction for this deep-freeze warehouse construction project. At least 32,000 m² Roma insulation panels type P are fixed directly onto the rack structure which also serves as the load-bearing structure of the deep-freeze warehouse.

A deep-freeze warehouse construction project requires a design that is properly worked out in advance. This design forms the basis for the multidisciplinary building team to draw up a detailed plan. The best solutions for insulation, space saving and energy saving were chosen in terms of quality and savings. The strict French construction legislation and fire-resistance (insurance) requirements were also provided for. All the insulated building materials and services used were certified and inspected by the French certification organisation Apave, which also performed inspections during the entire construction phase. Upon delivery, a blower doortest was performed to check the airtightness of the deep-freeze warehouse of Kloosterboer Harnes.